ACKNOWLEDGMENTSThe 1973 restoration and interpretation of Wagaman Mill was a difficult and tedious task. Substantial effort was expended in attempting to recreate the historic facility in as much of its original character as possible. The efforts of many individuals were necessary to accomplish the objective. Space does not permit a complete listing. In order for the project to be implemented, it was necessary that several agreements be negotiated with landowners. Paramount to the success of the entire project was the, complete cooperation of W.H. (Huck) Wagaman, Mary Wagaman, and their daughter, Carol Wagaman Davis, who provided a long-term, 50 year lease to the Wheel House of the Old Mill, and substantial portions of the north and south shore of the North Skunk River. The bridge access area, west of the mill, is included In the agreement, along with the fishing access east of the mill and along the north shore. The former owner of the mill, Larry Melsa, Larry's wife Joyce, and sons Greg and Brad are acknowledged for their cooperation in agreeing to the long-term lease of the Wheel House. Special recognition and appreciation is herein extended to "Huck" Wagaman, who expended many hundreds of hours of personal time in conversation, consultation and direct physical labor in the implementation of the restoration project. Without question, this assistance made the task easier than what it might have been. The variety of gears, wheels, shafts, and miscellaneous gadgetry was assembled under "Huck's" direction, based on his recollection of the "Way things used to be." Since 1998, the Lynnville Historical Society has raised money and undertook the repair of the existing mill building. They have also added displays on local history. Last, but not least, the project was only made possible by the financial provisions of the residents of Jasper County, through our local Conservation Fund, and from financial input from the Bureau of Outdoor Recreation, U.S. Dept. of Interior. Without question, a project of this nature is time consuming and expensive to implement. However, it had to be done. The "Old Mill," a unique vestige and remnant of a bygone past--a magnificent reminder of our pioneer heritage, has been preserved for posterity. Page 2 HISTORY OF THE OLD MILLBy Dennis BlackPrior to the railroads advent in Iowa, small villages were established at suitable locations which would provide a natural site for a mill. Such a site was located by John R. Sparks, who with his family, migrated from Lee County to Jasper County in 1845. The family located in Section 10 of what is now Lynn Grove Township. With a cash capital of $25.00, one span of horses, two yoke of oxen, two yoke of steers and two wagons, John, his wife Elizabeth, and their ten children built one of the first log cabins in Lynn Grove Township. Sparks first endeavor was the construction of a small, paddle-wheel saw mill, commenced in 1845, and completed in 1846. In 1847, Sparks commenced construction of a grist mill, completing the structure in 1848. Power for the mill originated from a mill pond, the resultant backwater of a large wooden dam constructed across the North Skunk River. According to published historical records, Spark's mill was a superior operation to that hitherto put up with by the pioneers, who had much trouble in obtaining good flour at the "illy-built makeshift" of mills in this section of Iowa. The mill was greatly prized by the people of the entire county, saving as it did three days conveyance to Oskaloosa over uncertain streams and poor roads. The buhr (grinding) stones of the Sparks Mill were said to have been of the best French make. Note: Credit is given to Eric Sloan, who wrote a book and did the drawings of the mill stones and the various dresses for them |

Vertical

|

|

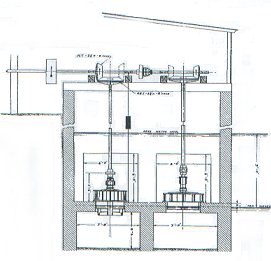

The above illustration is that of a water powered, steel turbine. Specifically, this is a standard "Trump" turbine, called so because of its manufacture by the Trump Mfg. Co., of Springfield, Ohio. A turbine, exactly as shown, is contained in the Wheel House at the Wagaman Mill, and when activated, produces the power to run the various machinery. This turbine was ordered in March, 1919, from the Trump Mfg. Co., by J.A. (Fred) Wagaman.

At the south end of the footbridge, the old, Leffel turbine rests for viewing by the mill visitor. This relic of antiquity was one of the first ever constructed by the James Leffel and Co. of Springfield, Ohio. Specifically, this turbine was ordered by the Arnold Brothers of Lynnville on July 18, 1968, and was shipped by rail on September 17, 1868. For nearly 80 years this turbine functioned in the "Old Mill" in producing the power for split-wooden wheels and belts to operate the buhr stones in grinding wheat and corn for flour. During periods of low water, an alternate source of power, being steam, was utilized in order to continue production.

In 1919, when Fred Wagaman purchased the new Trump turbine, his intention was to utilize both turbines concurrently. This was accomplished, and resulted in a greater power to operate additional equipment. One such piece of equipment was a 371/2 K.W., A.C. Generator. Electrical output of up to 2300 volts served the needs of the residents of Lynnville and surrounding rural area for many years. This generator rests in the "pit" in the Wheel House of the Mill, and functions today as it did for many years. As an item of interest, and for comparative purposes, the 26 inch diameter Trump turbine, the one in operation in the Wheel House today, produces 28.9 horsepower with a seven foot head (depth of water in which turbine rests). At full operation, the turbine would utilize 2,732 cubic feet of water per minute, and provide 134 revolutions per minute of the vertical steel shaft.

Page 7

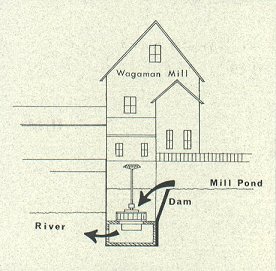

It is frequently difficult for the mill visitor to properly understand the mechanics of the operation. The above sketch can best illustrate the process.

Simply, the function of the dam is to provide a reservoir of water for powering the machinery. Also, very important is the fact that the dam "holds" this reservoir of water at a higher elevation than that of the river below the dam. This difference in water elevation is known as "head."

A wooden head gate allows water to flow into the Wheel House and maintain an elevation exactly as that of the mill pond behind the dam. Once this water is in the Wheel House, the only way it can escape to the river below is either through the Trump turbine, resting in the bottom of the pit, or through a tail gate. However, the tail gate is opened only to allow for repairs of equipment or for rapid release of head water.

Gates on the turbine are opened by means of a steering wheel, attached to the turbine by a long pipe. Once these gates are open, water is forced through the turbine, forcing the "runner" fins to rotate. The runner is directly attached to the vertical line shaft, which in turn is geared to the horizontal shaft. Again, the "head," generally being 5 to 6 feet, provides the force necessary to turn the runner inside the turbine.

Water, manipulating a very simple machine, transfers the energy needed by man to make his task and daily job much easier.

Page 8

|

|

|

Page 9

Side View, Facing West Towards Wheel House

The above rendering is an original of December 21, 1918, prepared by the Trump Manufacturing Company of Springfield, Ohio, for J.A. Wagaman of Lynnville. The drawing was prepared for the purpose of identifying the locations of the two turbines, the one in the left being the new Trump turbine, and the one on the right the 1868, old Leffel turbine. Both turbines were arranged so as to work together in the production of power to operate the mill. New vertical and horizontal line shafts were required, as were appurtenances of steel gears with wooden cogs (teeth) and keys (shims). A gear and braking mechanism allowed the Trump turbine to operate independent of the old Leffel turbine.

The mechanism illustrated above was that which provided the power for the Old Mill to operate and function. As the turbine gates were manually opened, and water allowed to flow through, the turning runner (blades) were a direct attachment to the vertical line shaft. Power was transferred to the horizontal line shaft from the vertical, and the result was the turning of the split wooden pulleys. Belts from the pulleys were attached to the various machinery in the mill, including grinders, grain cracking equip-ment, separators, sifters, and the 2300 volt generator. Some of this equipment is on display in the Wagaman Mill today.

Essentially, the mill mechanically operates today much as it did in history. The difference is that only the Trump turbine rests in its respective pit, while the old Leffel turbine is on display at the south end of the foot bridge.

Page 10

The initial restoration and interpretation of the "Old Mill" was a project sponsored by the Jasper County Conservation Board. Dennis Black, Executive Director, implements the program and policies of the Board. Mark Wagner, Naturalist, is responsible for arranging mill tours and interpretation in the water-powered area of the wheel house.

Past, retired Board Members who were actively involved in the restoration include A.L Nuzum, Baxter; Edwin Wilson, Newton; and Dr. T.E. Fitzpatrick, Lynnville.

Funds for the restoration of the Old Mill and construction of the associated park were derived from grants-ia-aid under the Federal Land and Water Conservation Fund Program, and monies from the Jasper County Conservation Fund.

Current restoration and operation of the Wagaman Mill and Museum is a cooperative effort between the jasper County Conservation Board and the Lynnville Historical Society. Ownership of the Wagaman Mill was deeded to the Lynnville Historical Society by the Wagaman and Melsa Families.

The goal of the Jasper County Conservation Board is the establishment of quality park, recreation, conservation and outdoor education system which gives the most service to residents of Jasper County and the State of Iowa. To reach this objective, we energetically promote programs and interests in conservation and the preservation of our natural re-sources.

The Jasper County Conservation Board welcomes any recommendations or comments you might have. Please address them to:

JASPER COUNTY CONSERVATION BOARD

1030 W 2nd St S

NEWTON, IOWA 50206

(641)792-9780

Brochure layout

by Dennis H. Black and Mark D. Wagner

Jasper County Conservation Board

|

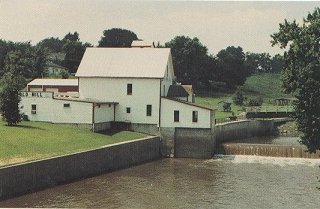

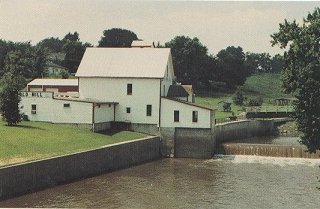

Information and photos provided with permission of the Jasper County Conservation Board Touring Information(641) 792-9780Open every Sunday from Memorial Day until the end of September from 1-4 pm. The Wagaman Mill, also known as the Old Mill, was constructed in 1846. It has been used as a saw mill, carding mill, flour mill, feed mill and as a generating station for electricity. Complete interior restoration and interior interpretation of the wheel house is available for public viewing during the summer only. Placed on the National Register of Historic Places. |

To inquire about volunteering for the IAGenWeb Project enter here and Join Our Team!

To inquire about volunteering for the IAGenWeb Project enter here and Join Our Team! |

Server space for the IAGenWeb Project site is provided by the Friends of Iowa Gen Web

Server space for the IAGenWeb Project site is provided by the Friends of Iowa Gen Web |