ST. ANSGAR MILL — After 100 years of operation, the St. Ansgar Mill is

going to electric power. Until three years ago the mill's grinding

operation was done completely by water power. About one-fourth of the

grinding still done, is done by water power -- but this will soon change.

St. Ansgar mill to have electricity

By MRS. CLYDE ROEHR

Globe-Gazette Correspondent

ST. ANSGAR-The old saying "A lot of water has gone over the

dam," is quite true at the old St. Ansgar Mill on the Cedar River at St.

Ansgar.

Water rights were issued in 1854 and the following year

a brewery and grist mill were erected along the river by M. Sorenson and

N. H. Lund. Very little work was done there and operation was sold to

parties who moved the machinery to Minnesota.

In 1861, just 100 years ago, the first mill was erected by

W. P. Bowan. Considerable changes have taken place during the century but

water has powered the mill** for many years. This is the only mill in the area,

and perhaps in Iowa, still using water power for grinding.

After Bowan sold to S. V. R. Smith Co. it changed hands several times before

G. W. P. Bownan acquired it and built the first dam and a fine-stone mill.

Farmers donated their time and helped build the first brush and log dam.

This original dam is still there about 20 feet back of the present cement

dam in use now.

Pioneer farmers who had hauled their wheat to Mc-Gregor,

which was a trip of several days, thought it best to have their own mill

close at hand, and their object was to sell the wheat they raised and get

flour back.

Later S. V. Smith again acquired it and in February, 1871,

when Mr. McCarthy purchased it there was excellent water power running five

run buhrs and three sets of patent rollers. During his operation he made

and shipped flour in Old Betz brand bags to Chicago. In 1876 the old mill

burned and was rebuilt.

McCarthy sold to Mrs. Emily J. Haines in July, 1887.

In 1893 the bridge over the Cedar River was erected just north of the

mill. Later the mill again was destroyed by fire. Records show the tenant

in possession at the time fled the country after threatening a law suit

against one of the insurance agents, who had placed the insurance on the

grain instead of the mill.

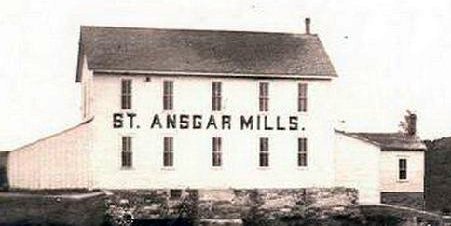

Martin Klindt bought the dam and power in 1900 and built

the present mill building still in use. R. Helfritz bought the mill from

Klindt and operated it until 1914 when it was sold to Otto and Robert

Boening. Several years later Otto took over the business alone.

Flour grinding during this period was the main business,

at first it was operated under an exchange schedule of 37 pounds of flour

for one bushel of wheat (no charge) or 32 pounds of flour and 14 pounds of

bran and midds (no charge). His flour bins held 14,000 pounds ready for

exchange.

Lowest prices for 50 pounds of flour was 85 cents. During

World War I the price went up to $2.50. Wheat came from all parts of

Mitchell County and surrounding counties. Grinding capacity was 24,000

bushels of wheat a year. During 1915 and 1916 Boening built a 10 foot

concrete dam directly west of the mill that is still in use today. Robert

Kleinworth, its present owner says "it has worn down about six to eight

inches during the years. This dam at one time furnished electricity for

St. Ansgar on a limited basis, from dusk to 9 p.m. only," says Kleinworth.

It was the town's only source of electricity for a time.

On March 1, 1930, Sherwin Kleinworth became sole owner and

in 1947 his son Robert went in partnership with him. Last May, Robert took

over the business.

Water power continued to be the source of power until

three years ago when the Kleinworths added an electric grinder as the

volume of business required more power than water could provide. Presently

they use electricity for three fourths of the power. In the very near

future Klein worth plans to convert entirely to electricity; thus making

water power become history and also being the last water powered mill.

The water wheel resembles a 60-in diameter wood drill.

It lies parallel to the river and the gates adjust the amount of water

entering the enclosed wheel, which in turn adjusts the speed. There are

gates on the north end of the mill building which can be closed to shut off

the water if necessary.

Robert Kleinworth says there are two good reasons we're

converting completely to electricity. First, there is just not power

enough to handle all the grinding business, and second, it is quite a

chore when the old wheel needs repairing. Only Dad and I know how to

repair it, and getting down in that cold water especially in severe

weather is really a task."

(Mason City Globe-Gazette Tuesday, February 7, 1961)

|