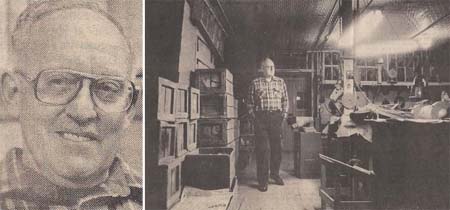

Leon H. Hosch & the Lee Aluminum Foundry

HOSCH, WYLIE, DARLING

Posted By: Errin Wilker (email)

Date: 3/17/2013 at 19:48:42

Foundry’s Founders are Family

Leon H. Hosch of New Albin turned a problem into an opportunity when 26 years ago, at age 37, he found himself during a recession with a wife, three children and no job.All of his adult life, Hosch had worked in foundries. First in Davenport, Iowa, in 1939 for the Blackhawk Foundry and Machine Co., where he helped make dome castings for the B-29 airplanes; and in 1946 (upon his return from World War II service in the Pacific) with the Lansing Co., a manufacturer of aluminum castings.

After beginning as a 55-cent-an-hour welder, Hosch was superintendent of the Lansing foundry when the owner’s death caused the company to close in 1956.

Jobs were hard to come by in those days, he recalls, especially in Hosch’s hometown of New Albin, population 675.

So Hosch gathered his courage, “borrowed to the hilt,” and, with the help of his wife, Vivian, turned his basement hobby (creating unique, miniature aluminum castings of toys, name plates and novelties) into a business.

His first customer was a boat manufacturer in Pipestone, Minn., for whom he made bow castings and transomes. More orders from other customers came in and the business expanded into the kitchen and living room, then out into the garage.

“It looked like a shanty town around my house for awhile,” Hosch says.

For two years the couple ran the entire operation. “Vivian could do everything," Hosch boasts. She supervised the assembling room, did nearly all of the clerical and accounting work and when needed could operate any machine in the plant.

The fledgling foundry’s first employee was Donna Darling. Like her employers, Ms. Darling became adept at all aspects of the operation. She riveted, grinded, drilled, painted, packaged and boxed the aluminum products.

It's that employee flexibility, and a “start-to-finish” method of production, that Hosch believes may be credited for the company’s eventual success.

Most small foundries concentrate on only one or two phases of the process. However, Hosch produced from the initial aluminum ingot through the foundry, the assembly line, the painting and the packaging. That type of production is more characteristic of larger firms.

As Hosch’s Lee Aluminum Foundry and Manufacturing Co. grew, it diversified. He bought many of the toy patterns from the defunct Lansing Foundry and began manufacturing miniature toy farm machinery for Ben Franklin stores. He also began producing swing set parts for a playground equipment manufacturer, soap dishes and turnbuckle castings for airplane hangars.

Perhaps his most well-known customer is the Little Brown Church in the Vale, Nashua, Iowa. The Lee Foundry makes souvenir replicas of the famous church, which sell as banks and music boxes at the popular tourist site.

In 1959, Hosch bought New Albin’s Dreamland Ballroom, which for 20 years prior had been the town‘s dance hall and before that was a Ford garage. He converted the 70-by-96-foot structure into the foundry.

Today Lee Foundry is New Albin’s second largest employer with 10 full-time workers, whom Hosch describes as “the best crew we’ve ever had.” During the peak production months of summer and fall, Hosch has employed 21 workers. (Weber Construction is the towns’ largest employer.)

Hosch remains modest about his success. “We’re just little peewees down here,” he says. “We're not getting wealthy, but it‘s a good living.”

From its inception, Lee Foundry has been a family affair. At one time or another each of the Hosch children have worked in the plant.

Jerry, 34, worked in the furnace room while in high school. He is now an employee at Outers Laboratories Inc., rural Onalaska.

Nancy, 36, worked as a packer and is now a beautician in Des Moines.

James, 38, also started working the family business while in high school. After a year of college and a few other jobs, he decided to return to the foundry full time in 1973.

This month James becomes the new owner of Lee Aluminum Foundry. Leon has decided to retire.

Hosch quips, “If a man is smart, he'll retire at 55; that‘s why I waited until I was 62.”

Hosch approaches retirement as he has most things in his life — with gusto. He’s planning to continue his work on the New Albin City Council (he‘s been a council representative for the past 25 years). He anticipates increasing the amounts of traveling, camping, square dancing and fishing he does with his wife.

He is also a past commander of the New Albin Veterans of Foreign Wars post, a former member of the Eastern Allamakee School Board and past president of the Catholic School’s Athletic Club.

Hosch anticipates continued prosperity for his son James and the family business. “Foundries are the basis for all industries,” says Hosch.

He says foundries do especially well during depression times because castings are somewhat cheaper than some weldings would be.

Besides, like Leon Hosch, James has the help of his family. His 15-year-old son Jimmy is already working at the plant after school.

Source: La Crosse Tribune, La Crosse, WI, 31 Jan. 1982

----- -----

Leon Harold Hosch

September 8, 1919-October 8, 2011Vivian (Wylie) Hosch

November 17, 1920-February 27, 2008

(see her obituary on the Obit Board)

Leon H. Hosch Obituary

Allamakee Biographies maintained by Sharyl Ferrall.

WebBBS 4.33 Genealogy Modification Package by WebJourneymen