![]()

Santa Claus' Workshop Started as a button factory, the Lansing Company now devotes half of its time to Christmas toys by Betty DeWitt Wittmer ~ Photos by John Jaqua  |

Children are big business at Lansing where the Lansing

Company, Inc., annually produces millions of toys for boys and

girls throughout the world.

Any family from America to Africa may have a "Lansing Christmas" this year. Lansing Slik-Toys are favorite gifts for all age youngsters. There is a wooden train or peg-pounding board for the babe in the household, a small ironing board for sister, and a complete set of miniature farm machinery for the little man. Also the Christmas package may be decorated with bright metal bells which were carded by the Lansing Company.

Nestled against an Iowa hillside two blocks from the Mississippi River, the Lansing factory owes its origin to that very river -- for J. M. Turner in 1897 founded the factory to make pearl buttons from Mississippi River clam shells. Developing his grandfather's small plant into an important industry has been the life work of Leo T. Hufschmidt, now president of the company. Today only half the business is in buttons, as the Slik-Toy line, which was started in 1942, has rapidly enlarged.

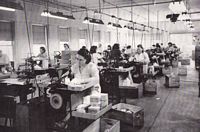

Buttons are prepared for marketing

in the carding room

In 1938, the firm quit manufacturing buttons and became a button-jobber, expanding into what is considered the nation's biggest button business outside New York. Buying buttons from every part of the globe, the Lansing Company places them on cards and distributes them to retailers at the rate of some 25,000,000 cards per year. Precisely filed in library-like stacks, the line includes at least 180 varieties of buttons in as many as ten different size and colors each. Colored metal bells are carded in another division of the button plant.

Simultaneously, off the assembly lines on the other side of the plant, roll miniature scale models of tractors, farm wagons, mowers, plows, discs, harrows, combines, cornpickers and manure-spreaders -- over 30,000 a day, with little trains and a few other toys produced at a lesser rate.

Toy tractors are boxed by Mrs. Clarence Spinner |

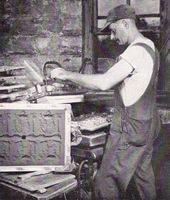

Earl Mack makes molds for tractors |

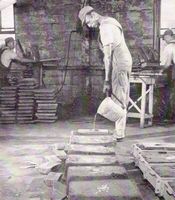

Richard McKee ladles alloy aluminum into sand molds |

The toy tractors are sprayed with paint by Mrs. Otto Pottratz |

Key personnel include the keen-witted president with "brains

in his fingers," Leo Hufschmidt, 68; John Brophy, 38,

vice-president and sales manager, who with Mr. Hufschmidt is also

a descendant of the founder; young Norbert Spinner, plant

superintendent; and Floyd Johnson, who is in charge of the

foundry where the company makes all its own aluminum castings.

Hufschmidt and Brophy own the controlling interest.

N.P. Spinner, J.C. Brophy and Leo T.

Hufschmidt

confer on a production problem.

Visitors are welcomed at the plant. Everyone who tours the light, airy factory and streamlined offices on Main Street and the foundry on the riverbank asks the same question: How did a button business turn to making toys? Let John Brophy, dynamic manager of sales tell you. "It was sheer accident," declares Brophy. "At the time, we were making some costume jewelry as a sideline and had a limited amount of woodworking equipment on hand when World War II started. Mr. Hufschmidt, who enjoys designing, whittled out some wooden jeeps and army cars, just for fun. In the same spirit, we took them to a variety display in Chicago. "Well, we found ourselves in the toy business overnight! We had to work fast to handle the orders. Like Topsy, the line 'just grew'. We made some toys from wood and a few from plastic. After V-J Day, we had to decide whether to stick to toys or not. We stuck! Because metal was available again, and we prefer its sturdiness, we decided to make our toys from aluminum." Now the well-built Slik-Toy line centers about "wheel goods," the Lilliputian scale models of farm machines. Oliver corporation is the largest buyer. Minneapolis-Moline, Massey-Harris and Ford Motors are also important purchasers.

The Lansing Company has around 15,000 active accounts for its two lines and keeps 25 button-and-toy salesmen on the road from coast to coast in the United States and three in Canada. Chief outlets are the farm implement manufacturers, independent variety stores, toy shops, syndicates like Woolworth and Kresge and jobbers. Postage and freight costs alone in 1935 totaled over $50,000. "Our selling peak is June through October, but manufacturing continues at a fairly steady pace all year long," explains Brophy. "We plan our output at the first of the year and must gamble on expected sales."

In addition to the factory and business office on Main Street, the Lansing Co., maintains a foundry by the riverside and two warehouses where its products can be stockpiled until ordered. A single order from an implement maker like Oliver may include as many as 400,000 toy machines. Though some orders are shipped out by mail or freight, the majority are trucked from Lansing.

As colorful a figure as one of his company's products is the president. Tall, slim and white-haired, Leo Hufschmidt keeps an active control of the plant, often designing a new machine or process to improve the output. Hufschmidt has a deep love for the river which started his career. He built his own houseboat, a steel-hulled, luxuriously appointed cruiser with radio and phone communication system, television set in the lounge, a competely equipped galley, and sleeping and eating accommodations for 12 persons. He and his wife enjoy cruising up and down the river, tying up wherever the fancy strikes them. Hufschmidt had so much fun building the boat, that he has now started another in the yard beside his foundry. Lansing residents fondly whisper that the houseboat hobby may sometime turn into another important sideline of the Lansing Company.

Employing 250 persons, 95 percent of whom live in Lansing, the company is the lifeblood of the quiet little Iowa town. Directly or indirectly, all Lansing's 1800 residents depend upon the unusual combination of industries for their existence. A large percentage of the employees are women, many of whom are over 50 years of age. The firm offers such employee benefits as paid vacations, two daily "coffee breaks" and a life insurance plan paid by the company. Though working entirely with millions of tiny buttons, bells and toy parts, the Lansing Company operates at a high speed and precision in an atmosphere that might be envied by many major industries.

~~

- source: The Iowan Magazine,

Shenandoah, Iowa, January 1955

- transcribed by Errin Wilker